giovedì 1 novembre 2012

venerdì 12 ottobre 2012

giovedì 6 settembre 2012

domenica 2 settembre 2012

martedì 5 giugno 2012

RETRO FISH TOA 5'6" - BUILDING NOSE 1 of 2

lunedì 21 maggio 2012

RETRO FISH TOA 5'6" - THE ITALIAN JOB

Saturday,

one of the most important HWS website has dedicated an article to TOA

!!

Don’t

You believe it?

See

now our page “ARTICLES” or click directly on www.woodensurfboards.blogspot.com

Thanks

again Grant !

sabato 19 maggio 2012

RETRO FISH TOA 5'6" - SHAPING RAILS 1 of 2

SHAPING

RAILS 1 of 2

(Work

time – 3-4 h each side)

After

gluing all layers it’s time to progress to one of the most

important part of the board…the rail shape is closely

related

to the performance and manoeuvrability.

For

this step is fundamental to follow strictly

the design and to have in mind exactly the building procedure.

In

summary we have take 6(six) section each

30cm and using CAD we have drawn for each section 3 triangles

corresponding to the material to remove. After having marked the

sections on the board we started to mark one point on deck and one on

side corresponding to the hypotenuse

of the first triangle.

To

link all the points

of the deck making a line and the same for the side.

Now…rasp

away the triangle for all length.

A

lot of work but

it’ s amazing to see more and more the board take shape.

.... following pics shown our method:

|

Take

away extra material

|

|

Six sections

|

|

A

long splint is very useful to link all points

|

|

Rail marked and ready for rasping

|

|

First

step completed

|

giovedì 17 maggio 2012

RETRO FISH TOA 5'6" - BUILDING RAILS

BUILDING

RAILS

(Work

time – 30 min +

24 h glue drying time each

layer !)

Finally

we start building rails…!

We

have to glue two layers of Samba plywood and five layers of cork,

total 30mm thickness each side.

|

At

this stage the board is ready for building rails

|

|

First

samba layer has to be drilled to save weight

|

Protect

bottom & deck with paper and to glue first layer using big

elastics and some weight to maintain desired shape during dry time

(24 H)

|

First

layer and pressing technique

|

|

First

layer and pressing technique

|

|

Remove

as material as possible to the first layer

|

|

Apply

glue to the first layer

|

|

Second

layer pressed with the same pressing technique

|

|

Once glued remove

extra wood

|

Lay down roll of cork on each side to take the template to cut off, after to apply glue and press it waiting 24 H for drying. Repeat the sequence for each cork layer.

|

Cork

cutting operation

|

|

First

cork layer glued and clamped

|

venerdì 4 maggio 2012

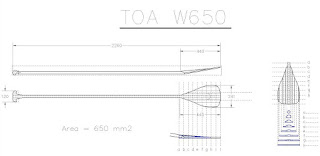

SUP PADDLE - TOA WAVE 650

RETRO FISH TOA 5'6 - INTERNAL BLOCKS FOR FCS FINS AND LEASH

FCS

internal blocks for fins & leash

(Work

time – 1 hour +

24 h glue drying time)

Now

It’s

time to glue in all the backing blocks for the fins and leash plugs.

In

order top save time and money we have used reject of samba plywood to

glue each other.

|

surface

preparation before gluying blocks

|

|

Gluying

of the fin blocks in place

|

|

internal

fin blocks top view

|

|

Gluying

of the leash block in place

|

RETRO FISH TOA 5'6" - INTERNAL TAIL AND NOSE PREPARATION

Internal

Tail & Nose PREPARATION

(Work

time – 2 hours +

24 h glue drying time)

Internal

tail & nose reinforcements shall be shaped to match bottom curves

and internal rail splints.

Its

necessary to use paper template (extract to design) for positioning

correctly of al splints.

Once

the glue is dried use rasp for obtain the desired shape.

|

alignment

phase on the actual shape using paper template

|

|

preparation

& gluying of internal nose reinforcements

|

|

UP:

gluying of int. tail reinforcements DOWN:alignment and Gluying of

upper int rail reinforcements

|

|

before

& after wood carving

|

|

fish

tail takes shape..!

|

Iscriviti a:

Commenti (Atom)